-

аппаратуры нефти испытывая

-

Аппаратуры испытания антифриза смазывая масла и тавота

-

Оборудование для испытаний дизельного топлива

-

Оборудование для испытаний масла трансформатора

-

Аппаратура испытания питания

-

Фармацевтические аппаратуры испытания

-

Оборудование для испытаний пищевого масла

-

Аппаратуры химического анализа

-

Оборудование для испытаний масла Lube

-

Аппаратура теста муки

-

Аппаратуры испытания еды

-

Оборудование для испытаний сырой нефти

-

Оборудование для испытаний гидравлического масла

-

Тестер горячей точки

-

Кинематический тестер выкостности

-

Тестер температуры замерзания

-

Прибор проникания конуса

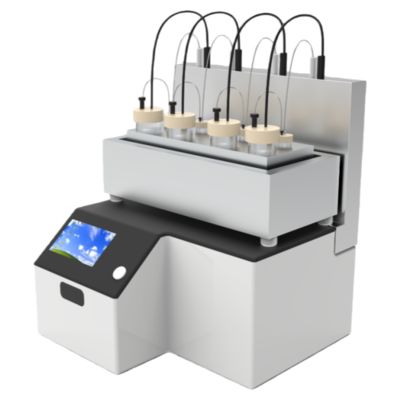

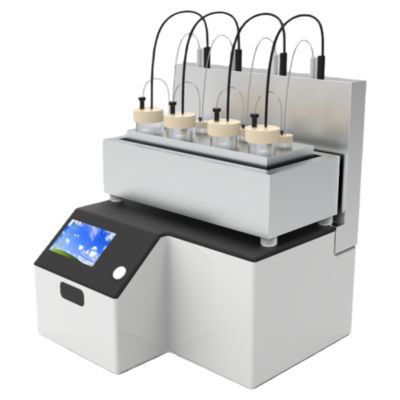

Automatic Oxidation Stability Tester PT100 Temp Sensor Tallow Vegetable Fat ISO 6886

| Место происхождения | КИТАЙ |

|---|---|

| Фирменное наименование | Shandong Shengtai Instrument Co.,Ltd |

| Сертификация | GB/T21121 ISO 6886 AOCS Cd 12b-92 |

| Номер модели | ST149 |

| Количество мин заказа | 1 |

| Упаковывая детали | Деревянный ящик |

| Время доставки | 7-15 рабочих дней |

| Условия оплаты | T/T. |

| Поставка способности | 10000 комплектов/год |

| Режим отображения | дисплей LCD цвета 7-inch | Метод отопления | Металлическая ванна нагрев |

|---|---|---|---|

| Датчик Temp | Импортированный датчик температуры PT100. | Temp устанавливая ряд | КТ ~ 220 ℃ |

| Размер инструмента | 420*390*480 мм | Вес инструмента | 26 кг |

| Выделить | Automatic oxidation stability tester PT100 sensor,Vegetable fat oxidation tester ISO 6886,Tallow stability tester with temperature sensor |

||

ST149 Automatic Oxidation Stability Tester

ST149 automatic plant oil oxidation stability index (OSI) is designed and manufactured in strict accordance with GB/T 21121-2007 determination of oxidation stability of animal and vegetable oils (Accelerated oxidation test). It is controlled by a single chip microcomputer and displayed by a liquid crystal LCD. The results are automatically generated and printed

OSI (oxidative stability index): during the determination, hot air at a certain temperature is introduced into the oil sample to accelerate the oxidation of glycerol fatty acids and produce volatile organic acids. The air brings the volatile organic acids into a conductive chamber, and the indoor water dissolves the volatile organic acids and ionizes ions, thus changing the conductivity of the water. The computer continuously measures the conductivity of the conductive chamber. When the conductivity rises sharply, it indicates the arrival of the end of the induction period, and the period before that becomes OSI time.

Controlled by single chip microcomputer, the time conductivity curve of the sample can be drawn and the oxidation stability time of the oil can be calculated automatically; The instrument has sample measurement switch and status display.

Main application areas

● Plant oils and fats: soybean oil, sunflower seed oil, rapeseed oil, palm oil, peanut oil, etc;

● Animal fats and oils: butter, fish oil, lard, etc;

● Oil containing products: cosmetics, margarine (directly measured), cereal products, biscuits, nuts, bacon, sausages, meat, etc. (measured after extracting oil);

● Research on the antioxidant properties of antioxidants;

● Determination of oxidation stability of FAME (fatty acid methyl ester)

● Determination of stability of copper catalyst for light oil oxidation

Technical Specifications

| Standard | GB/T21121 ISO 6886 AOCS Cd 12b-92 |

| Dispiay mode | 7-inch color LCD display |

| Heating method | Metal bath heating |

| Temp sensor | Imported PT100 temp sensor |

| Output format | CSV or Excel , USB |

| Heating module | single group heating or multiple group heating , Set the temperature of each heating hole separately |

| Instrument size | 420 * 390 * 480mm |

| Instrument weight | 26kg |

| Package size | 560 * 400 * 530mm |

| Temp setting range | RT ~ 220 ℃ |

![]()

● Specialized diaphragm pump with precise flow control and constant flow rate

● Real time measurement data of conductivity meter.

● Data display: Real time display of conductivity during oil oxidation process and induction period

● The length of the induction period represents the stability of the oil

● Storage method: The experimental results can store 1999 sets of historical data for easy retrieval

● Result output: It can also be equipped with a USB drive output function to output data to the PC for long-term storage

● It can be used for single machine touch screen experiments or computer-controlled instruments for experiments

★ Input extension: barcode scanner can be selected to scan and input sample number and other information (optional)

● Equipped with specialized calculation software, it can automatically calculate the oxidation stability time

● Instrument display: The instrument itself has a color display screen, which can display the temperature of each heating module, gas flow rate, measurement cell status, and conductivity value of each measurement position

Heating module

● Heating method: Metal bath heating

● Sample size: 3g (recommended by national standards)

● Temp control range: RT ~ 220 ℃

● Temp control accuracy: ± 0.1℃

● Protection function: It has over temperature protection function and can automatically stop when the temperature exceeds 260 ℃.

● Temp control method: Four sets of temperatures can be individually controlled, and the four sets of temperatures can be set to the same temperature or different temperatures.

| Heating method | Metal bath heating |

| Sample size | 3g (recommended by national standards) |

| Temp control accuracy | ± 0.1℃ |

| Protection function |

Overtemperature protection, Automatically stop when the temperature exceeds 260 ℃ |

Gas flow control module

● The instrument is equipped with a built-in diaphragm air pump

● Specialized electronic air flow pump

● Air flow range: 1-30 L/h (25 ℃, normal atmospheric pressure 101.325kpa)

Conductivity measurement system

● Conductivity measurement range: 0-300uS/cm (0-500uS/cm)

● Conductivity resolution: 0.1 US/cm

Software computing module

● Equipped with a powerful database data management system: capable of automatically calculating oxidation stability time based on results.

● Automatically calculate the maximum second derivative of the curve to determine the induction time

● Automatically deduce the induction time of the sample at room temperature of 20 or 25 degrees Celsius

Note: The appearance pictures, dimensions, volume, and weight of the instrument are for reference only. If there are any updates to the instrument, there may be slight changes without prior notice.

Packing list

| No. | Name | Quantity | Unit | Note |

| 1 | Oil oxidation stability tester | 1 | Unit | |

| 2 | Computer | 1 | Unit | |

| 3 | Reaction tank | 4 | Piece | |

| 4 | Special plug for reaction tank | 4 | Piece | |

| 5 | Measurement pool | 4 | Piece | |

| 6 | Measurement pool specific plug | 4 | Piece | |

| 7 | Vent pipe | 1 | Set | |

| 8 | Detecting conductivity sensor | 4 | Root | |

| 9 | Gas filtration device | 1 | Set | |

| 10 | Special accessories for connecting ventilation pipes | 1 | Set | |

| 11 | Special calculation software for oil oxidation stability tester | 1 | Set | |

| 12 | Power cord | 1 | Root |

Shandong Shengtai Instrument Co., Ltd. provides the following quality assurance for the instruments sold to you:

----The provided instrument materials are brand new, meet quality standards, and have a manufacturer's certificate of conformity;

----The materials and main components provided meet the technical requirements specified in the technical documentation;

----The overall quality assurance period of the equipment is one year (excluding normal wear and tear of vulnerable parts).

----We are responsible for free maintenance of any instrument quality issues that occur during the warranty period. Due to equipment malfunction caused by the user's responsibility, we are responsible for repairing and charging reasonable fees.

----Lifetime discounted supply of parts for equipment, and lifetime maintenance and repair of the entire machine.

----After the expiration of the warranty period, if the user needs maintenance and technical services, we will only charge a cost fee.

Packaging and Delivery

1. Packaging of goods: standard wooden or cardboard boxes.

2. Internal packaging: Elastic pearl cotton packaging product, hardwood board+strong bandage to fix corners.