-

аппаратуры нефти испытывая

-

Аппаратуры испытания антифриза смазывая масла и тавота

-

Оборудование для испытаний дизельного топлива

-

Оборудование для испытаний масла трансформатора

-

Аппаратура испытания питания

-

Фармацевтические аппаратуры испытания

-

Оборудование для испытаний пищевого масла

-

Аппаратуры химического анализа

-

Оборудование для испытаний масла Lube

-

Аппаратура теста муки

-

Аппаратуры испытания еды

-

Оборудование для испытаний сырой нефти

-

Оборудование для испытаний гидравлического масла

-

Тестер горячей точки

-

Кинематический тестер выкостности

-

Тестер температуры замерзания

-

Прибор проникания конуса

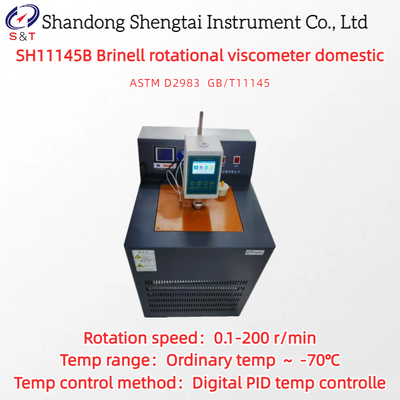

Вискометр вращения Бринелла Обычная температура −70°С Скорость вращения 0,1-200 р/мин ASTM D2983

| Ряд температуры | Обычная температура ‐70°C | Метод управления температурой | Цифровой ПИД-регулятор температуры |

|---|---|---|---|

| Конфигурация ротора | 1–4 ротора (стандартно) 0 роторов (опционально) | Диапазон вязкости | 1-6 миллионов МПа. с (cp) 15 МПа. s ниже, рекомендуется использовать ротор 0 # |

| Кривая вязкости по температуре | Сенсорный дисплей | Ошибка измерения | ± 1% (FS) ньютоновская жидкость |

| метод охлаждения | Компрессор охлаждение | Функция времени | Сенсорный экран отображает функцию синхронизации |

| Выделить | Ротационный вискозиметр Бриннеля для смазочных масел,Вискометр вращения с диапазоном -70°C,Вискометр |

||

SH11145B Вискометр вращения Бринелла

The SH11145B Low Temperature Brinell Viscometer for Lubricating Oil is designed and manufactured strictly in accordance with GB/T11145-2014 Determination of Low Temperature Viscosity of Lubricants using the Brockfeldt Viscometer MethodОн подходит для обнаружения автомобильных жидкостных смазочных материалов с вискозностью от 1 до 6000000mPa.s, таких как масло редукторов, масло гидравлической трансмиссии, промышленное и автомобильное гидравлическое масло.Метод определения вязкости скорости сдвига автомобильных жидкостных смазочных материалов предполагает помещение образца в холодную ванну при температуре испытания, соединяя вискометр Бургундии и шпиндель, выбирая соответствующую скорость вращения,и поддержание постоянной температуры в течение 2-16 часов до измерения низкотемпературной бургундской вязкости образца.

Основные технические характеристики, параметры и характеристики эксплуатации:

| Стандартный | ASTM D2983 GB/T11145 |

| Диапазон температуры | Обычная температура ‐70°C |

| Способ контроля температуры | Цифровое управление температурой PID |

| Скорость вращения | 0.1-200 оборотов/мин |

| Конфигурация ротора | 1-4 ротора (стандарт) 0 роторов (необязательно) |

| Диапазон вязкости | 1-6 млн. МПа. с (cp) ниже 15 мПа. с, рекомендуется использовать ротор 0 # |

| Кривая температуры вязкости | Дисплей с сенсорным экраном |

| Ошибка измерения | ± 1% (FS) Ньютоновская жидкость |

| Повторяемость | ± 0,2% (FS) Ньютоновская жидкость |

| Экранное отображение | Вязкость, скорость сдвига, напряжение сдвига, скорость вращения, температура, процент крутящего момента, число ротора и максимальное измеряемое значение вязкости выбранного ротора при текущей скорости вращения,и т.д. |

| Функция синхронизации | На сенсорном экране отображается функция времени |

| Интерфейс данных | оснащенный интерфейсом печати RS232, может напрямую подключаться к интерфейсу печати компьютера |

| Функция печати | Подключение к микропринтеру для печати экспериментальных данных |

| Способ охлаждения | Охлаждение компрессором |

![]()

Примечание:Если есть какие-либо обновления прибора, могут произойти незначительные изменения без предварительного уведомления.

Shandong Shengtai Instrument Co., Ltd. предоставляет следующую гарантию качества для инструментов, проданных вам:

---- Предоставленные материалы приборов совершенно новые, соответствуют национальным стандартам качества и имеют сертификат соответствия от производителя;

---- Предоставленные материалы и основные компоненты соответствуют техническим требованиям, указанным в технической документации;

---- Общий срок обеспечения качества оборудования составляет один год (за исключением нормального износа уязвимых частей).

---- Мы несем ответственность за бесплатное обслуживание любых проблем с качеством инструмента, которые возникают в течение гарантийного периода.мы несем ответственность за ремонт и взимаем разумные сборы.

---- Пожизненное скидку на поставку деталей для оборудования, и пожизненное обслуживание и ремонт всей машины.

---- После истечения гарантийного периода, если пользователю необходимо обслуживание и технические услуги, мы будем взимать только стоимость сбора.

Список упаковки

| Число | Имя | Количество | Единица | Примечание |

| 1 | Хозяин | 1 | Единица | |

| 2 | Роторы 1-4 | 1 | Установлено | |

| 3 | Ротор No.0 | 1 | Установлено | |

| 4 | Адаптер питания | 1 | Установлено | |

| 5 | Защитная рама | 1 | Кусок | |

| 6 | База | 1 | Кусок | |

| 7 | Подъемная колонна | 1 | Установлено | |

| 8 | Датчик температуры | 1 | Кусок | |

| 9 | Перекрестная стойка | 1 | Корень | |

| 10 | Шестерковый ключ | 1 | Кусок | |

| 11 | Стрелковый ключ | 1 | Кусок | |

| 12 | Руководство пользователя, сертификат соответствия, гарантийная карточка | 1 | Установлено |